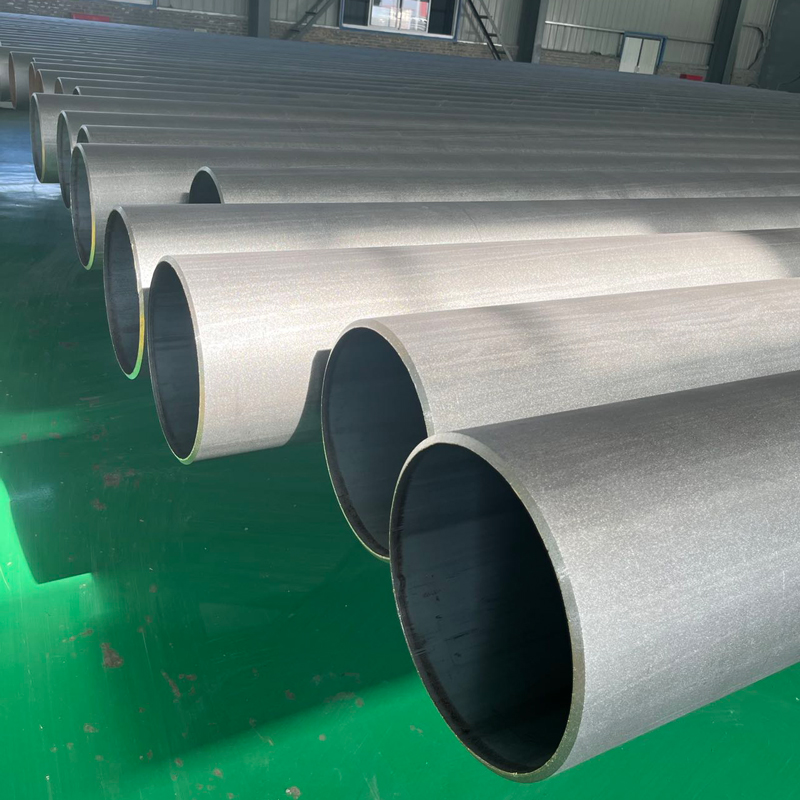

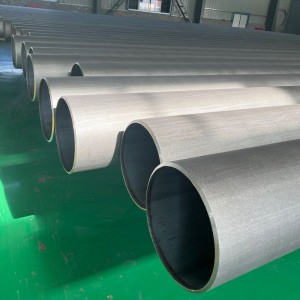

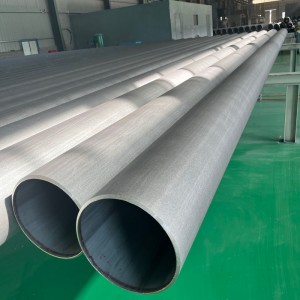

Mafuro eEpoxy Akabatana neFusion Awwa C213 Standard

Hunhu hwezvinhu zve epoxy powder

Simba remagetsi rakanyanya pa23℃: zvishoma 1.2 uye zvakanyanya 1.8

Kuongorora sefa: yakakwira 2.0

Nguva yegel pa 200 ℃: pasi pe 120s

Kuchenesa nekuputika kwemhepo

Nzvimbo dzesimbi dzisina chinhu dzinofanira kucheneswa nekuputika zvichienderana neSSPC-SP10/NACE Nhamba 2 kunze kwekunge zvataurwa neimwe nzira nemutengi. Patani yekuputika kana kudzika kweprofile kunofanira kuva 1.5 mil kusvika 4.0 mil (38 µm kusvika 102 µm) zvakayerwa zvichienderana neASTM D4417.

Kupisa

Pombi yakacheneswa inofanira kupiswa patembiricha iri pasi pe260℃, panobva kupisa hapafanirwe kusvibisa pamusoro pepombi.

Ukobvu

Upfu hwekuputira hunofanira kuiswa papombi yakapiswa nekupisa kwakaenzana kwe 305μm kunze kana mukati. Hupfu hwakanyanya hahufanirwe kudarika 16 mils (406μm) kunze kwekunge zvakurudzirwa nemugadziri kana kuti zvakatarwa nemutengi.

Kuedza kushanda kwe epoxy nesarudzo

Mutengi anogona kutsanangura mimwe miedzo yekuona mashandiro e epoxy. Maitiro ekuyedza anotevera, ese anofanirwa kuitwa pamipendero yekuedza pombi yekugadzira, anogona kutsanangurwa:

1. Kuboorwa kwechikamu chakasiyana.

2. Kupinda kwemukati.

3. Kuongorora kupisa (DSC).

4. Kuoma zvachose (kukombama).

5. Kunyikwa mumvura.

6. Mhedzisiro.

7. Kuedzwa kwekupatsanurwa kweCathodic.