suma:

Muchikamu chepombi, vatambi vaviri vakuru, vasina musono uye vakasungwa, vanga vachirwira hukuru.Nepo ese ari maviri achishanda zvakafanana, ane akasiyana hunhu anoita kuti ave akakodzera kune chaiwo maapplication.Mune ino blog, isu tinotarisa mune nuances yemusono pombi vs welded pombi, ongorora misiyano yavo uye mashandisiro, uye pakupedzisira kukubatsira iwe kunzwisisa kuti ndeupi rudzi rwakakunakira zvaunoda.

Seamless pombi:

Seamless pombi, sezvinoreva zita racho, inogadzirwa pasina majoini akasungwa kana seams.Iwo anogadzirwa nekuburitsa yakasimba cylindrical billet kuburikidza netsvimbo ine perforated kuti iite mhango chubhu.Iyi nzira yekugadzira inovimbisa kuenzana uye kuenderana muchimiro chepombi, ichichibvumira kukurira kudzvinyirirwa kwepamusoro uye tembiricha.

Zvakanakira seamless pombi:

1. Simba uye Kuvimbika:Seamless tubing ine simba rakatanhamara uye yakavimbika nekuda kwekumanikidza kwayo kwemukati chiyero uye isina majoini akasungwa.Hunhu uhwu hunovaita kuti vaenderane nezvishandiso zvinoda mwero wepamusoro wekusimba, sekutakura oiri uye gasi uye maitiro ekunatsa.

2. Aesthetics:Seamless tubing inozivikanwa nekutsvedzerera, kupenya kwayo, zvichiita kuti ive sarudzo yakakurumbira yezvivakwa zvezvivakwa, zvikamu zvemotokari, uye fenicha yepamusoro.

3. Corrosion resistance:Mapombi asina musono anowanzo kuratidza kwakanakisa kusaita ngura, kunyanya kana yakagadzirwa nezvinhu zvakaita sesimbi isina tsvina kana alloy musanganiswa.Hunhu uhu hunobatsira pamaapplications anosanganisira kusangana nezvinhu zvinoparadza kana nharaunda dzakakasharara.

Welded pipe:

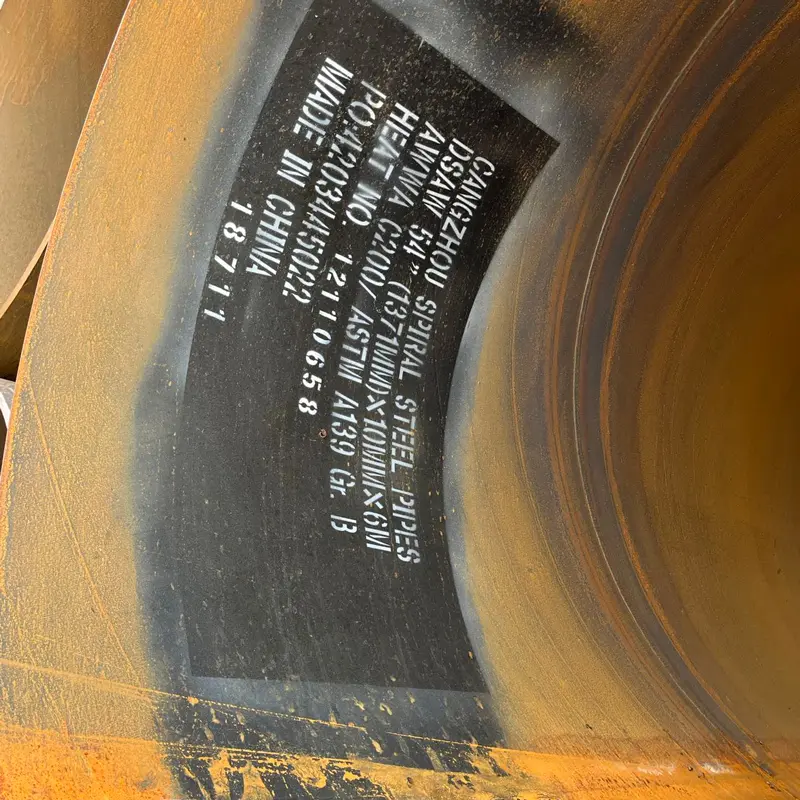

Kusiyana nepombi isina musono,welded pombiinoumbwa nekukungurutsa simbi yakatsetseka kuita cylindrical shape kuburikidza nenhevedzano yema rollers.Mipendero yemutsetse inozobatanidzwa pamwe chete neakasiyana-siyana welding tekinoroji senge electric resistance welding (RW), longitudinal submerged arc welding (LSAW) kana helical submerged arc welding (HSAW).Iyo welding process inopa mapaipi aya maitiro akasiyana uye hunhu.

Zvakanakira welded pombi:

1. Mutengo-kubudirira:Mapombi akasungwa anowanzo kudhura zvakanyanya kupfuura mapaipi asina musono, kunyanya nekuda kwekuita uye nekumhanya kwemaitiro ekugadzira.Saka nekudaro, ivo vanowanzofarirwa mumashandisirwo apo mutengo-unoshanda wakakosha, senge pombi, dhizaini yekumisikidza, uye yakaderera-kudzvanywa kwemvura yekufambisa.

2. Kusiyana-siyana:Mapaipi akasungwa ane hukuru hwakasiyana-siyana muhukuru uye maumbirwo sezvo achigona kugadzirwa mune akasiyana dhayamita, kureba uye ukobvu.Uku kuchinjika kunoita kuti vave vakakodzera kune dzakasiyana siyana dzekushandisa kubva kudiki pombi masisitimu kusvika kune makuru maindasitiri ezvivakwa.

3. Kuvandudza welding quality:Iyo welding process inoshandiswa kubatanidza mipendero yepombi inosimudzira kusimba kweiyo seam, kuve nechokwadi chekuita kwakavimbika kunyangwe pasi pekumanikidzwa kuri pakati nepakati.Hunhu uhu hunoita kuti welded pombi ikwane maapplications anosanganisira kutamisa mvura, kuvaka, uye pombi dzemvura mukati mezvivakwa.

Mukupedzisa:

Saka, ndeupi rudzi rwepombi yaunofanira kusarudza?Mhinduro iri mukunzwisisa zvinodikanwa zveprojekiti yako kana application.Seamless tubing inokunda munzvimbo dzakanyanya-kudzvanywa uye nepamusoro-tembiricha, nepo welded tubing inodhura-inoshanda uye inoshanda zvakasiyana.Ita sarudzo ine ruzivo nekufunga zvinhu zvakaita sesimba, kusimba, mutengo, uye zvinodiwa zvekushandisa.

Rangarira, pombi isina musono ndiyo epitome yesimba uye kuvimbika, yakanakira maapplication akakosha, nepo welded pombi inopa mhinduro dzinodhura uye kuchinjika.Pakupedzisira, nyanzvi yeindasitiri kana nyanzvi inofanirwa kubvunzwa kuti ione sarudzo inonyatsoenderana nezvido zvako uye inova nechokwadi chakabudirira uye chinoshanda mhedzisiro yeprojekiti yako.

Nguva yekutumira: Aug-25-2023